Transformation Log & Timber is

the low VOC formula of the original Transformation Log Stain by Sashco.

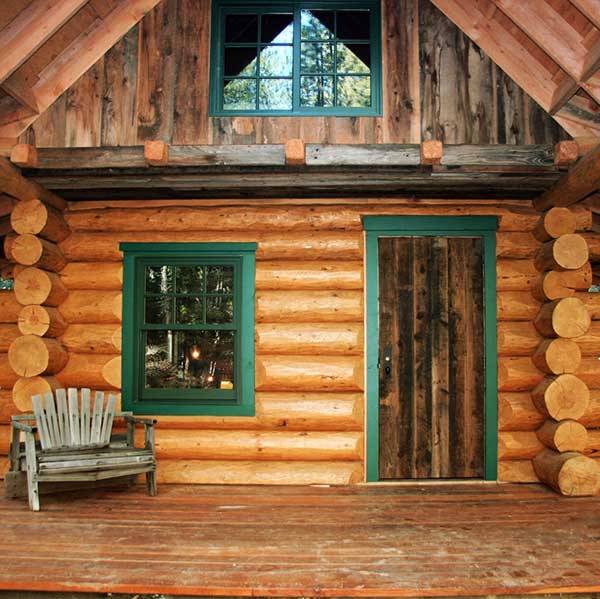

It will transform your logs and vertical woodwork from dull and

lifeless to rich and brilliant - especially for restoring older logs.

Transformation is excellent for restoration log work. Transformation Log

& Timber is the log home stain that's easy to remember because its

name describes what you want and what it provides, Transformation!

Perfect for new construction and restoration projects. Gloss sheen.

View the full data sheet here.

“A Better Way to Stain”

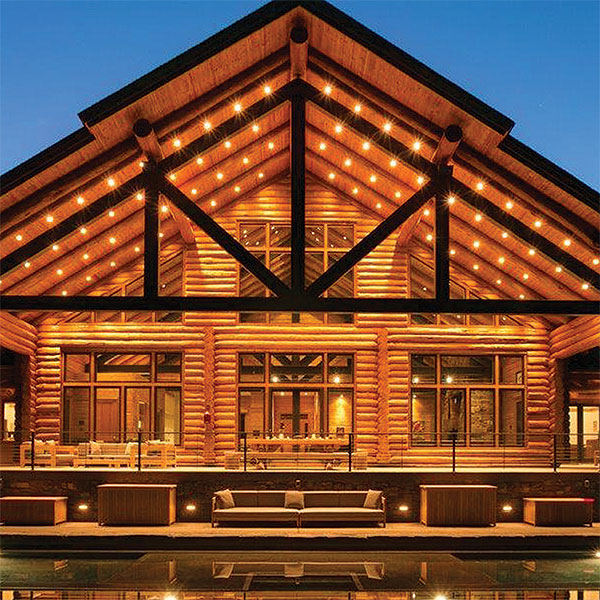

It‘s about Transformation: old and weathered logs

brought to life again, or timbers refreshed with color

when they were once only gray.

These are the results we want for our dream home,

but sometimes those results seem like a distant fantasy.

We’ve seen other log and timber homes scorched by

the sun and are afraid of the “big project” nature and

the hefty price tag of maintaining our own. Contrary to

common wisdom, having a great quality stain is only half

the battle. The other half is what is neglected the most:

routine maintenance. Over time, routine maintenance is

truly the key to easier and less expensive staining.

When done every 3-5 years, we find that routine

maintenance saves a lot of time and money by eliminating much of the prep work before staining. Simply do

a light power wash, allow the wood to dry, and apply a

maintenance coat. No sanding or stain removal necessary.

Your contractor will be happy you called him sooner

rather than later, and your pocketbook will be, too. It’s

that simple.

Use a quality stain like Transformation Stain® Log

& Timber and you’ll transform the look of your wood.

Practice routine maintenance, and you’ll discover a better

way to stain.

For Sashco’s complete guide on a better way to stain,

keep reading. You’ll find step-by-step instructions on the

following key topics:

Sampling

To get the look you want, sample the stain on your wood.

Prep

Proper prep starts you down the right path.

Application

Proper application of a quality stain ensures long-term

performance.

Routine Maintenance

Reduce long-term costs, time and effort.

View the full data sheet here.

Sampling

Proper sampling is where it starts. It is critical because the same stain can look very different

on various species of wood. Different prep and

application methods will also affect the final result.

Therefore, sampling on your wood is the only way to

make sure you get the color you want the first time.

It’s easy: on a small, inconspicuous test area (we

recommend a minimum 2 sq. ft. space), simply do

each step the exact same way you will on all of your

logs and timbers.

• Prep the wood.

• Apply the stain.

• Let the stain dry (both between coats and after

all coats are applied).

• If working with a contractor, don’t allow the

contractor to stain until you have thoroughly

discussed and demonstrated the look you want.

Show him/her the sample.

• Don’t stain all of your logs and timbers before

you verify that you’re achieving the look you

want. It is best if you can be on-site when staining starts.

Prep

Proper substrate preparation and application mean greater longevity,

better color, and better long-term performance.

• Make sure it sticks: If you are changing from one stain product to

another, contact us first. Transformation Log & Timber will adhere

to almost any surface that is properly prepped. Be aware that any

product already on the wood that contains waxes, non-drying oils,

silicones, or anything that forms thick layers on the wood, can interfere with the adhesion and penetration of Transformation Log &

Timber, or any stain, and must first be removed.

Cleanliness is a virtue: Starting with an absolutely clean surface

means better penetration and adhesion of the stain, which means

better longevity and a more beautiful finish.

• Media blast, vigorously power wash or sand wood surfaces using

an Osborn® brush or 60—80 grit sand paper to remove failing

stains and loose, unsound wood fibers, along with surface

contaminants.

• If mildew is present, apply Sashco’s CPR® in the brightener

strength according to the directions, or apply fresh bleach in a 4

parts water to 1 part bleach solution. Allow it to sit no more than

20 minutes, and then thoroughly rinse.

Fuzz be gone: For the best appearance, remove felting (wood fuzz)

with Osborn brushes, Sashco’s Buffy Pad system or 60—80 grit

sand paper once the wood is dry. Remove all sawdust with a broom,

compressed air or a leaf blower.

• Don’t delay: UV rays from the sun can damage cleaned wood surfaces in as little as 1 week; therefore, stain should be applied no

more than 2 weeks after wood prep is completed.

• Sunny with a chance of more sun: Plan to stain when the fore-

cast is predicting clear, rain-free weather that will extend 1-2 days

after the stain has been applied. If rain can’t be avoided, be sure to

protect the stain from direct rainfall for 1-2 days after the stain is

applied to prevent it from being washed off the surface.

Preserve, please: Apply Sashco’s PeneTreat® for protection

against wood rot and insects. Allow wood to dry at least 2-4 days.

(Use a moisture meter to check it!)

Osborn® is a trademark of Osborn International.

Application

Proper application of the stain, combined with the prep

you’ve already done, will complete the transformation of your

logs and timbers.

1. Stay dry:

Use a moisture meter to make sure wood is at or

below 19% moisture content level before applying stain.

Damp wood can prevent the stain from penetrating properly

and can eventually lead to peeling.

2. Say no to mildew:

Help keep surface mold and mildew at

bay by adding more mildewcides to the stain. We recommend Stay Clean I/E™. (now replaced with M-1)

3. Mix it up:

Thoroughly mix the stain. The preferred method

is to use a drill-driven, squirrel-cage type mixer. No matter

what method is used to mix the stain, you can ensure the

most consistent color by:

• Scraping all pigment off the bottom of the pail and

thoroughly mixing it in.

• Interblending pails with different lot numbers.

• Stirring the stain every 10-15 minutes throughout application to keep the pigments evenly distributed through

the stain.

4. Warm feelings:

Apply Transformation Log & Timber to

wood surfaces that are no colder than 40°F (4°C) and no

hotter than 90°F (32°C). Extreme temperatures will prevent

proper penetration and drying of the stain. Plan your work

so that surface temperatures fall within this range. Do not

apply to surfaces in direct intense sunlight and work in sections to avoid lap marks.

5. Spray it again, please:

a. Spray on one heavy coat of Transformation Log & Timber

stain. If only a brush is used, be sure to drench-apply the

stain. Don’t skimp.

b. Vigorously brush the stain, pushing it into the wood and all

cracks and checks, catching any drips. This promotes the

best adhesion and penetration, and leaves an even, consistent

coat of stain.

• Wait until the first coat is dry (24 hrs.), then apply a light

second coat of stain, spraying and back brushing as with

the first coat.

6. Bask in it:

Enjoy your beautiful log or timber home.

Routine Maintenance

Everyone knows that a $30 oil change twice a year beats a $2,000 mechanic’s bill. Routine maintenance on your logs or

timbers could be the difference between $2,000 every 3-5 years or $20,000 to completely redo the job. It’s truly the key to

“a better way to stain.”

1. Cleanliness is still a virtue:

• Lightly power wash your logs or timber to remove grease

spots, pollen, bird droppings and other surface contaminants.

• If mildew is present, apply Sashco’s CPR® in the cleaner

strength according to the directions, or apply fresh bleach

in a 4 parts water to 1 part bleach solution. Allow it to sit

no more than 10 minutes, and then thoroughly rinse. Allow

the surface to thoroughly dry. (This generally takes 2-4 days

in ideal weather. To know for sure, use a moisture meter to

check!)

2. One more coat, please:

• Spray on one maintenance coat of

Transformation Stain® Log & Timber. If only a

brush is used, be sure to drench-apply the stain

to ensure adequate coverage. Don’t skimp.

• Vigorously brush the stain, pushing it into the

wood, catching any drips. This promotes the

best adhesion and penetration, and leaves an

even, consistent coat of stain.

Clean Up

Clean brushes and equipment with mineral spirits. Hands may

be cleaned with citrus-based hand cleaners, and then washed

with soap and water. Follow local, state and federal guidelines

for disposing of empty cans or any unused product. For rag

disposal, see DANGER! statement.

Storage

Do not store in direct sunlight or hot conditions. Tightly

reseal opened containers and store at temperatures between

50˚F and 90˚F (10˚C - 32˚C). If skinned over, remove the skin

before thoroughly stirring the product.

View the full data sheet here.

Questions on maintaining the legacy of your wood structure? Give us a call- 1-800-359-6614

Pickup in store - or ship to your door -in whichever woods your cabin dwells.

Schroeder Log Home Supply, Inc.

1101 SE 7th Avenue

Grand Rapids MN 55744

1-800-359-6614